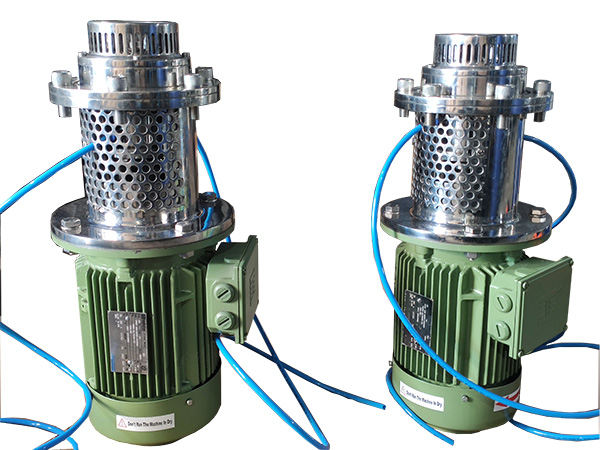

Bottom Entry Homogenizer

Bottom Entry Homogenizer

Artisan colloid mill is used for various applications such as Superfine. grinding, homogenizing, emulsifying, dispersing, mixing and extracting of liquids, ointments and highly viscous products in pharmaceutical, cosmetics, suspensions & emulsion industries.

Data Sheet & Models

| Model | Motor Power (HP) | Speed (RPM) | Batch Capacity (L) |

|---|---|---|---|

| BH-1 | 1 | 2880 | 5-20 |

| BH-2 | 2 | 2880 | 10-50 |

| BH-3 | 3 | 2880 | 50-100 |

| BH-5 | 5 | 2880 | 100-300 |

| BH-7.5 | 7.5 | 2880 | 150-600 |

| BH-10 | 10 | 2880 | 200-800 |

| BH-15 | 15 | 2880 | 300-1200 |

| BH-20 | 20 | 2880 | 500-1500 |

| BH-25 | 25 | 2880 | 800-2000 |

| BH-30 | 30 | 2880 | 1000-2500 |

| BH-40 | 40 | 2880 | 2000-4000 |

| BH-50 | 50 | 2880 | 3000-5000 |

Key Features

● Working capacity from 1 HP to 30 HP. ● Suitable for cream and emulsions of 20,000~80,000cps viscosity. ● Suitable for batch process with high efficiency. ● Pneumatic or hydraulic lifting system for easy cleaning and maintenance. ● Complete process of dispersing, high shearing, emulsifying and homogenizing. ● Work with different mixing tanks. ● All contact parts are made of SS304/316L/316 and mirror polished. ● The specifications of the top entry batch mixer comply with cGMP regulations. ● Power supply of 415V, 50Hz, 3 Phase.General Applications:

● Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste. ● Pharmaceuticals: ointment, dental composite, syrup, injection. ● Food: mayonnaise, dressing, jam, butter. ● Chemicals: polyester, synthetic fiber, shoe cream.Other Options

● Atmospheric or vacuum design available for different applications. ● Interchangeable work heads and screens of slotted and holed designs. ● Circular and rectangular flange designs for mounting on the vessel. ● Different combinations of batch mixer, agitator, high speed disperser and inline mixer for different mixing processes. ● Adjustable brackets for holding the manufacturing tank tightly. ● Control panel with variable speed drive for adjusting mixing speed. ● Explosion proof motors and electrics. ● Different power supply acceptable. ● Different pneumatic, hydraulic and electrical lifting devices for lifting the batch mixer for exchangeable tanks.