Multi-Stage Inline Homogenizer

Multi-Stage Inline Homogenizer

Artisan inline homogenizer is a high shear mixer for the manufacturing of viscous paste, cream, lotion and other emulsions in the pharmaceutical, cosmetic, food and chemical industries. It’s a vacuum emulsifier mixer and it is suitable for continuous mixing.

Data Sheet & Models

Double Stage Inline Homogenizer:-

| Model | Motor Power( HP ) | Rotation Speed, @50 Hz( RPM ) | Flow Rate, @ 1 cPs ( L/Hr ) | Inlet/Outlet( DN ) |

|---|---|---|---|---|

| DH-1 | 1 | 2880 | 1000 | DN25 / DN20 |

| DH-2 | 2 | 2880 | 2000 | DN25 / DN20 |

| DH-3 | 3 | 2880 | 3000 | DN40 / DN32 |

| DH-5 | 5 | 2880 | 5000 | DN40 / DN32 |

| DH-7.5 | 7 | 2880 | 7000 | DN50 / DN40 |

| DH-10 | 10 | 2880 | 8000 | DN50 / DN40 |

| DH-15 | 15 | 2880 | 12000 | DN65 / DN50 |

| DH-20 | 20 | 2880 | 16000 | DN65 / DN50 |

| DH-25 | 2 5 | 2880 | 25000 | DN65 /DN50 |

| DH-30 | 30 | 2880 | 30000 | DN65 / DN50 |

| DH-40 | 40 | 2880 | 40000 | DN80 / DN65 |

| DH-50 | 50 | 2880 | 50000 | DN90 / DN80 |

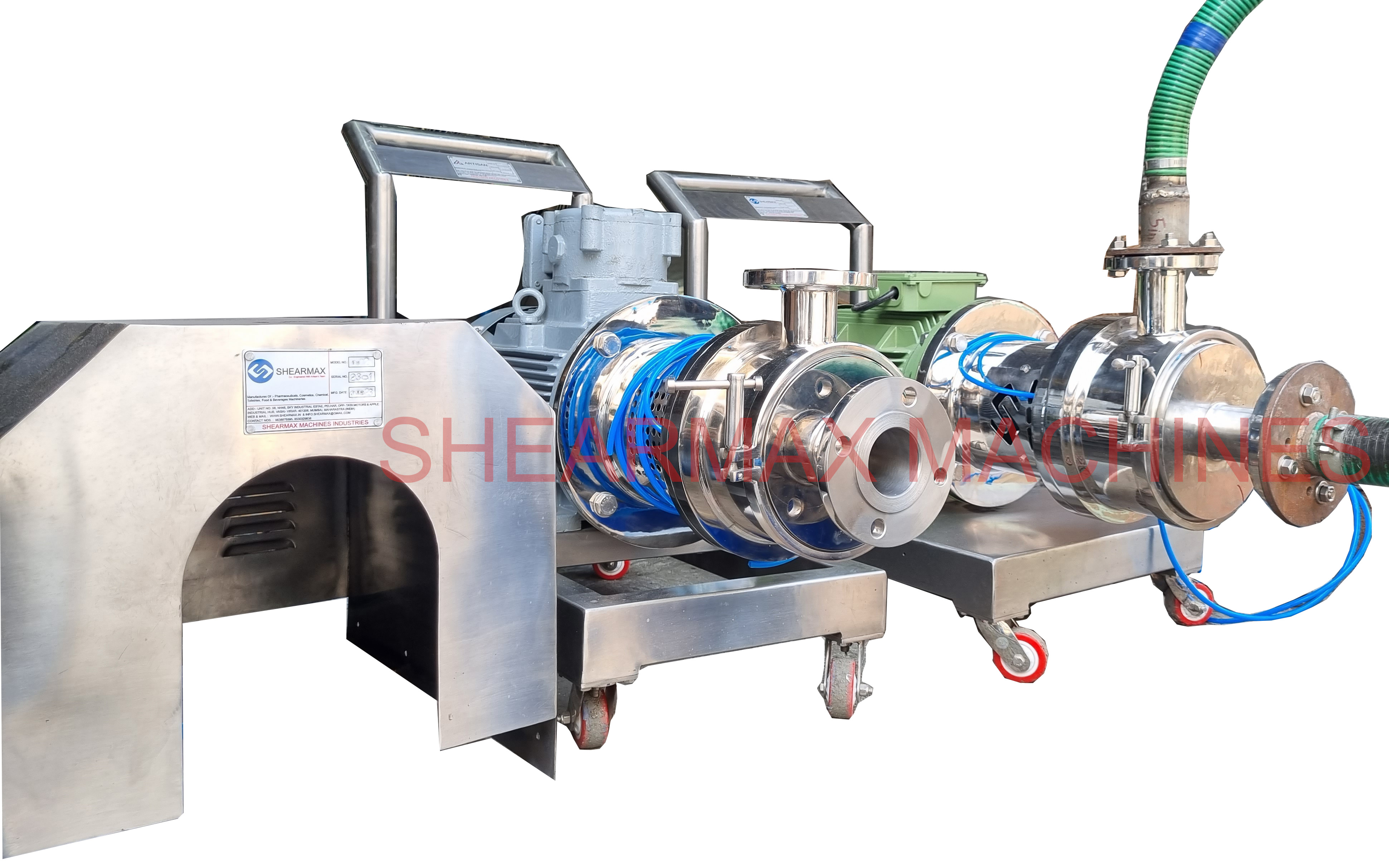

Three Stage Inline Homogenizer:-

| Model | Motor Power( HP ) | Rotation Speed, @50 Hz( RPM ) | Flow Rate, @ 1 cPs ( L/Hr ) | Inlet/Outlet( DN ) |

|---|---|---|---|---|

| TH-3 | 3 | 2880 | 2000 | DN32 / DN25 |

| TH-5 | 5 | 2880 | 5000 | DN40 / DN32 |

| TH-7.5 | 7 | 2880 | 7000 | DN50 / DN40 |

| TH-10 | 10 | 2880 | 8000 | DN50 / DN40 |

| TH-15 | 15 | 2880 | 12000 | DN65 / DN50 |

| TH-20 | 20 | 2880 | 16000 | DN65 / DN50 |

| TH-25 | 2 5 | 2880 | 25000 | DN65 /DN50 |

| TH-30 | 30 | 2880 | 30000 | DN65 / DN50 |

| TH-40 | 40 | 2880 | 40000 | DN80 / DN65 |

| DH-50 | 50 | 2880 | 50000 | DN90 / DN80 |

Four Stage Inline Homogenizer:-

| Model | Motor Power( HP ) | Rotation Speed, @50 Hz( RPM ) | Flow Rate, @ 1 cPs ( L/Hr ) | Inlet/Outlet( DN ) |

|---|---|---|---|---|

| FH-5 | 5 | 2880 | 3000 | DN40 / DN32 |

| FH-7.5 | 7 | 2880 | 5000 | DN50 / DN40 |

| FH-10 | 10 | 2880 | 7000 | DN50 / DN40 |

| FH-15 | 15 | 2880 | 10000 | DN65 / DN50 |

| FH-20 | 20 | 2880 | 12000 | DN65 / DN50 |

| FH-25 | 25 | 2880 | 20000 | DN65 /DN50 |

| FH-30 | 30 | 2880 | 25000 | DN65 / DN50 |

| FH-40 | 40 | 2880 | 35000 | DN80 / DN65 |

| FH-50 | 50 | 2880 | 40000 | DN90 / DN80 |

How It Works

>

>

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly.Stage 2

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.Key Features

● Flow rate by water from 1.5m³/h to 30m³/h. ● Complete process of dispersing, high shearing, emulsifying and homogenizing. ● Suitable for making cream, lotion, ointment and other emulsions of 5,000~100,000cps viscosity. ● Suitable for continuous mixing process of large quantity with high efficiency. ● High shear inline mixer with circulation pipes to the mixing tank for even homogenization. ● Products can’t bypass the precision rotor and stator work head. ● The self-pumping in line high homogenizer also works as a transfer pump for discharging finished product. ● Required cooling system for the mechanic seal for long high shear mixing time. ● Work with different manufacturing vessels. ● All Artisan Inline Homogenizer mixers are designed for CIP and SIP. ● All contact parts are made of SS316L/316/304. ● Sanitary clamp connections for inlet and outlet ports. ● The specifications of the inline continuous mixer comply with cGMP regulations. ● Power supply of 415V, 50Hz, 3 Phase.General Applications

● Pharmaceuticals: ointment, dental composite, syrup, injection. ● Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste. ● Food: mayonnaise, dressing, jam, butter. ● Chemicals: polyester, synthetic fiber, shoe cream.Other Options

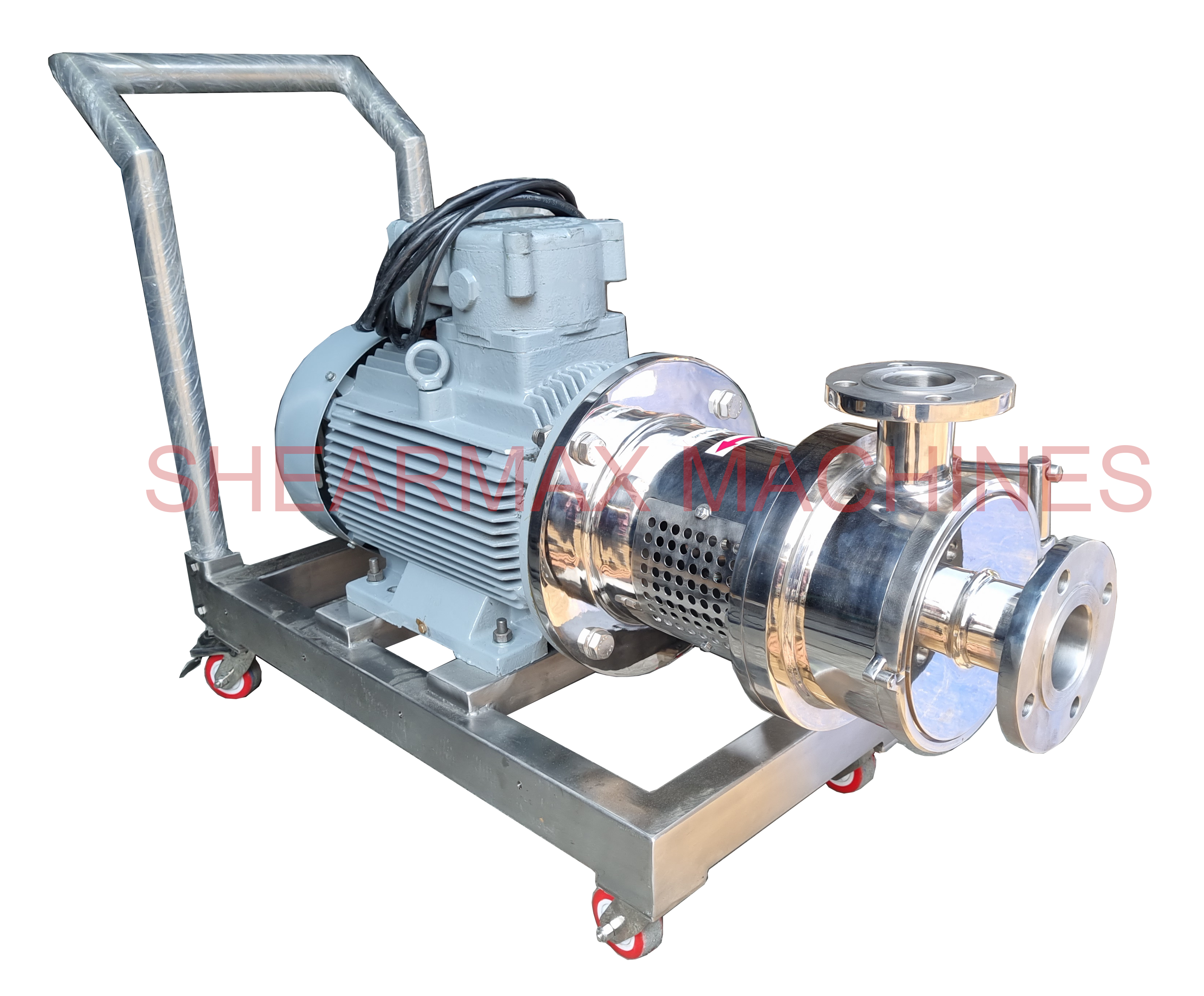

● Interchangeable work heads and screens of slotted and holed designs. ● Portable inline mixer with castor wheels and handle. ● Feeding hopper for adding powders and liquids. ● Different combinations of inline high shear mixer, agitator, high speed disperser and batch mixer for different processes. ● Control panel with frequency inverter for adjusting mixing speed. ● Different power supply acceptable.